| ↓ |

↓ |

ASTM D1238 |

ASTM D256 |

ASTM D1525 |

ASTM 638 |

ASTM D638 |

ASTMD638 |

↓ |

↓ |

| R370Y |

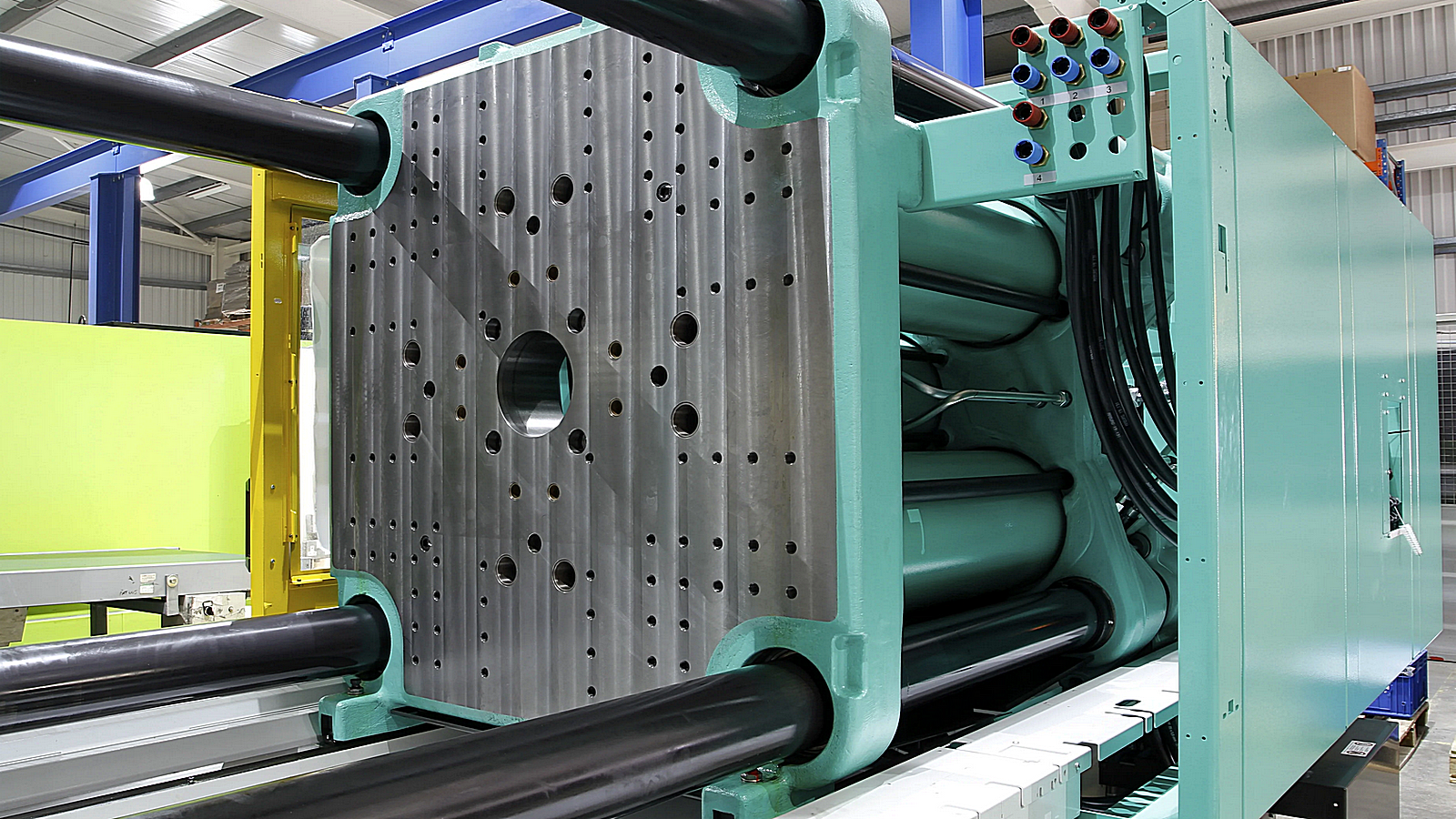

Injection |

18 |

6.5 |

135 |

28 |

<400 |

1200 |

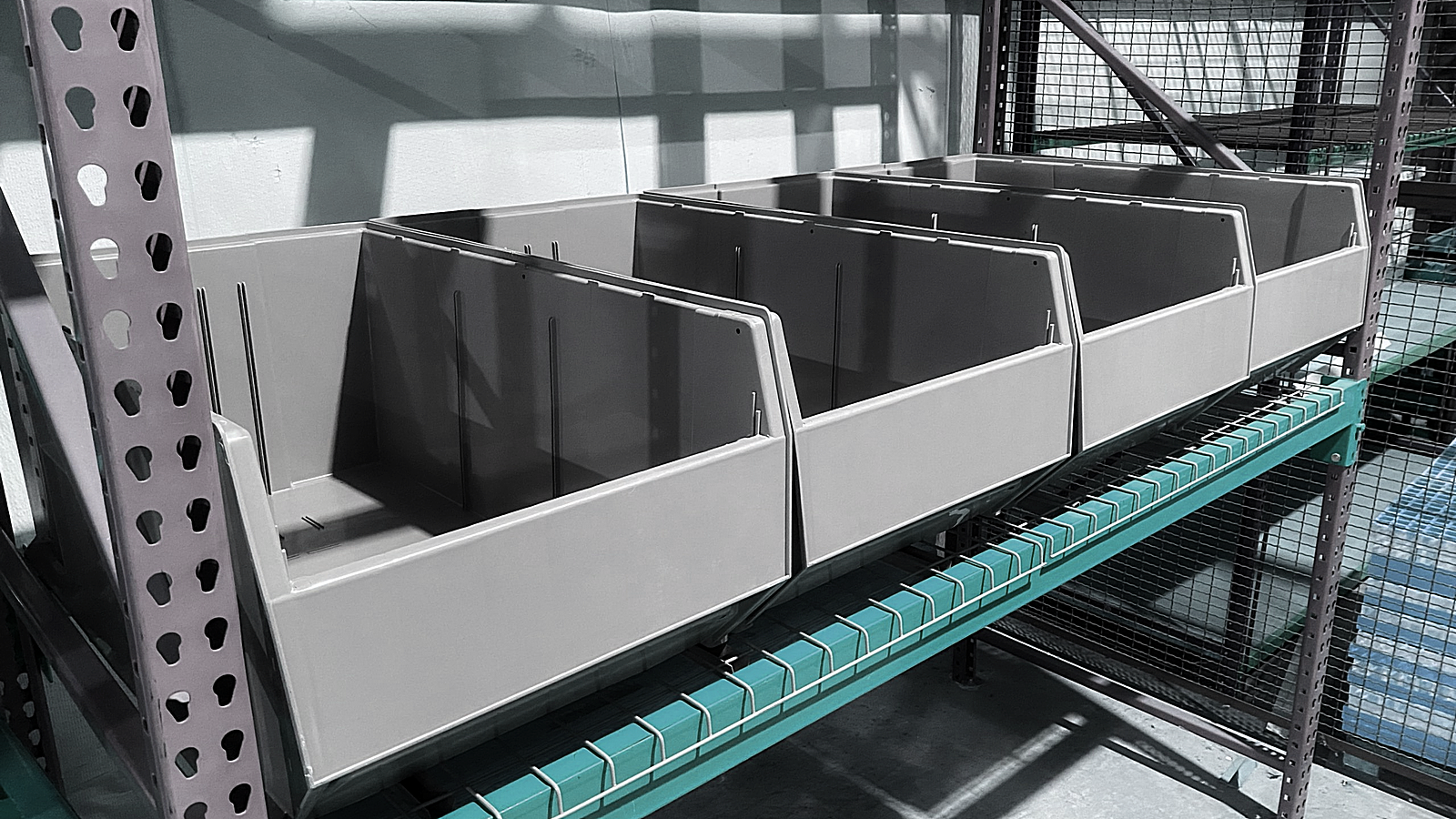

High Transparent container, Food container, Home appliance |

High Transparency, High gloss, Processability |

| R370F |

Injection |

18 |

5 |

130 |

26 |

<400 |

1000 |

Food container, Home appliance |

High gloss, Processability |

| R380F |

Injection |

29 |

4.5 |

130 |

25 |

<400 |

900 |

Food container, Home appliance |

High gloss, Processability |

| R380K |

Injection |

29 |

5.0 |

135 |

28 |

<400 |

1100 |

High Transparent container, Home appliance |

High Transparency, High gloss |

| R362Y |

Injection |

14 |

6.5 |

135 |

28 |

<400 |

1200 |

High Transparent container, Food container, Home appliance |

High Transparency, High impact strength, Stiffness, Heat resistance |

| R365Y |

Injection |

14 |

6.5 |

135 |

28 |

<400 |

1100 |

High Transparent container, Food container, Home appliance |

High Transparency, High impact strength, Stiffness, Heat resistance |

| R366Y |

Injection |

14 |

5.5 |

145 |

33 |

<400 |

1400 |

High Transparent container, Food container, Home appliance |

High Transparency, High impact strength, High stiffness, Heat resistance |

| R366S |

Injection |

14 |

5.5 |

145 |

34 |

<500 |

1400 |

High Transparent container, Home appliance |

High Transparency, High impact strength |

| R380Y |

Injection |

29 |

5.5 |

135 |

28 |

<400 |

1100 |

High Transparent container, Home appliance |

High Transparency, High gloss |

| R390Y |

Injection |

45 |

5.5 |

130 |

28 |

<400 |

1100 |

High Transparent container, Food container, Home appliance |

High Transparency, High impact strength, Stiffness, Heat resistance |

| R392Y |

Injection |

75 |

5 |

130 |

28 |

<400 |

1100 |

High Transparent container, Home appliance |

High Transparency, High gloss, Pocessability,Highimpact strength |

| R930Y |

Sheet |

4.5 |

6.5 |

140 |

28 |

<400 |

1100 |

Tansparent sheet |

High Transparency, High gloss, High impact strenght |

| R931Y |

Sheet |

3.5 |

8 |

135 |

31 |

<400 |

1300 |

Tansparent sheet |

High Transparency, High gloss, High impact strenght |

| R940F |

Sheet |

5.8 |

6.5 |

130 |

26 |

<400 |

900 |

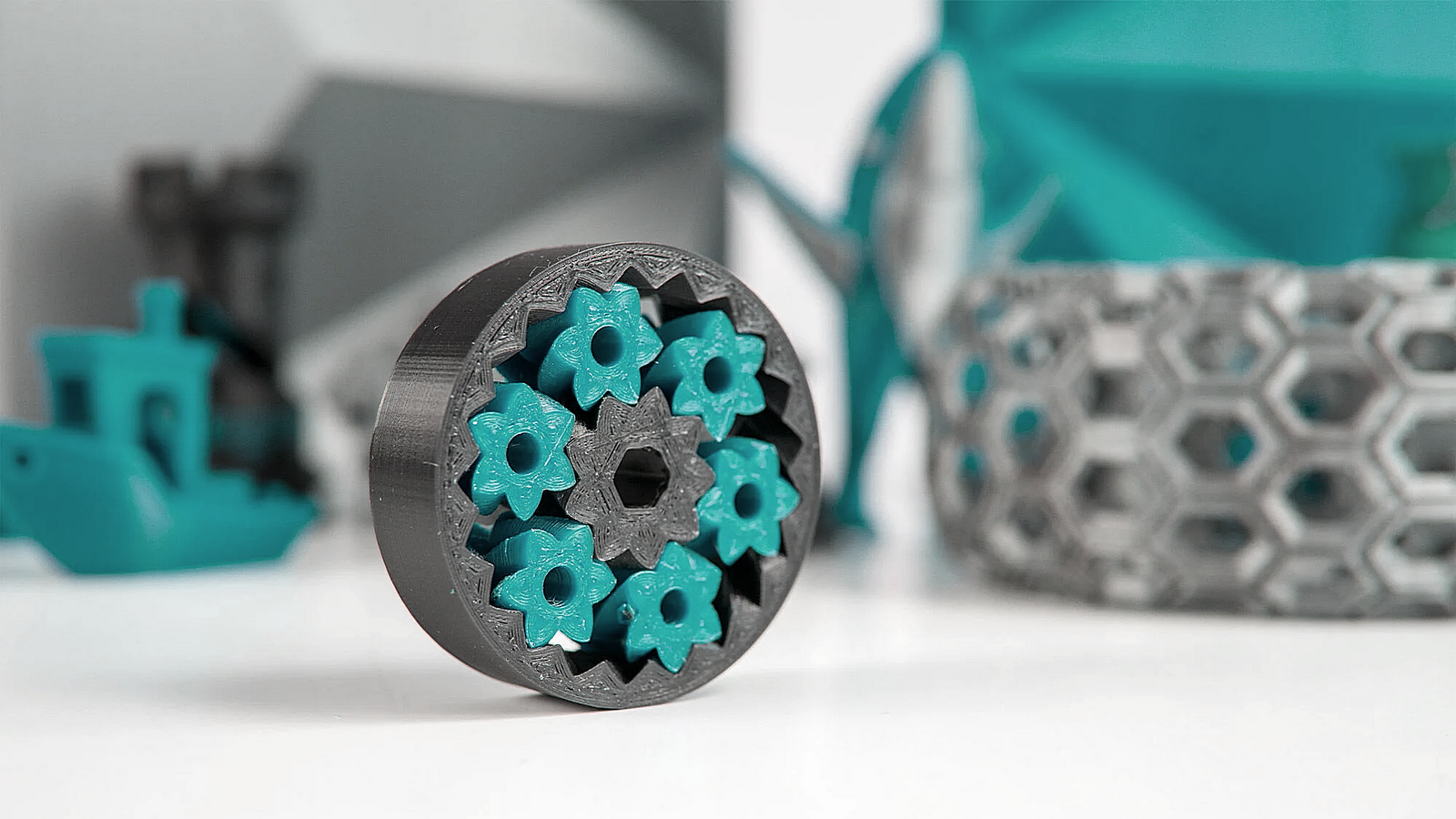

Expansion bead |

Excellent foaming properties, High stiffness |

| R940U |

Sheet |

5.8 |

6.5 |

130 |

26 |

<400 |

900 |

Expansion bead |

Excellent foaming properties, High stiffness, UV stability |

| R680S |

Coating |

28 |

4.5 |

125 |

25 |

<400 |

900 |

Lamination, Coating (Food packaging, Paper coating) |

Adhesive, Processability, Transparency, Stiffness |

| R520F |

Blow molding |

1.8 |

6.5 |

135 |

31 |

<400 |

1200 |

Medical container, Transparent container (IBM, ISBM) |

Autoclave Sterilization |

| R520Y |

Blow molding |

1.8 |

7 |

140 |

32 |

<400 |

1400 |

Transparent sheet, HighTransparent container (IBM, ISBM) |

High Transparency, High gloss |

| R140H |

Film |

6 |

6.5 |

130 |

26 |

<400 |

900 |

CPP co-extrusion, Retort pouch |

Glossy, Transparency, Low heat sealing temperature |

| R140M |

Film |

6 |

6.5 |

130 |

26 |

<400 |

900 |

CPP co-extrusion, Retort pouch |

Glossy, Transparency, Low heat sealing temperature |

| R150L |

Film |

8 |

5.0 |

135 |

29 |

<400 |

1200 |

IPP |

High Transparency, High gloss, High impact strenght, Anti-blocking, Slip performance |

| R151A |

Film |

7 |

5.5 |

130 |

26 |

<400 |

900 |

IPP |

High Transparency, High gloss, High impact strenght, Anti-blocking, Slip performance |