Petrochemical Products

Petrochemical Products with only one Attribute: Competitiveness

We know your needs for petrochemical products. We have negotiated and have solid and cordial relationships with the best world-class suppliers. We develop a unique position in the industry: a link between those who produce the best and need the best, with items that are fundamental in the global industry due to their versatility, while simultaneously rationalizing all factors, from technological and logistical, to financial matters.

A complete range of key products for each type of industry:

Featured Petrochemicals

Polyamides and superpolyamides: versatile polymers with exceptional properties

Polyamides

⦁ Polyamides are polymers that contain amide groups in their structure. They are known for their strength, durability and versatility.

⦁ Nylon is a common example of a polyamide. Nylon 6,6 (polyamide 6,6) is synthesized from hexamethylenediamine and adipic acid.

⦁ Polyamides are used in textiles, ropes, engineered parts and more.Poliamidas:

Superpolyamides

⦁ The term "superpolyamides" is not as common as "polyamides," but could refer to high-performance polymers with exceptional properties.

⦁ Some superpolyamides include nylon 11, nylon 12 and other modified derivatives with enhanced characteristics.

Nylon 6. Versatile in a wide range of applications.

Other Names and Identifiers:

⦁Polyamide 6

CAS Registry Number® 25038-54-4

European Chemicals Agency (ECHA): 928-264-0

Properties

1. Flexibility and toughness:

⦁Nylon 6 is known for its high flexibility and toughness.

⦁It is ideal for applications requiring impact resistant materials.

2. Water absorption:

⦁Nylon 6 has a higher tendency to absorb water compared to other nylons.

⦁This can affect its mechanical properties in humid environments.

3. Processability:

⦁It is easy to process using techniques such as extrusion and injection molding.

⦁It is used in the manufacture of textile fibers and molded parts.

Applications

⦁Textiles and fibers:

Hosiery, ropes and fabrics.

Brushes and bristles.

⦁Industrial components:

Gears and bearings.

Machinery parts.

⦁Packaging and packaging:

Filaments for 3D printing.

Bags and films.

Nylon 6/6: versatile in a variety of industrial applications

Other Names and Identifiers:

⦁Nylon 66

CAS Registry Number® 32131-17-2

European Chemicals Agency (ECHA): 608-706-6

Properties

Mechanical strength:

Nylon 6/6 exhibits high tensile and compressive strength.

It is ideal for applications requiring robust and durable components.

2. Thermal stability:

It can withstand moderate temperatures without losing its mechanical properties.

It is used in parts exposed to heat, such as engine components.

3. Stiffness and hardness:

Nylon 6/6 is stiffer than other nylons, making it suitable for gears and bearings.

Applications

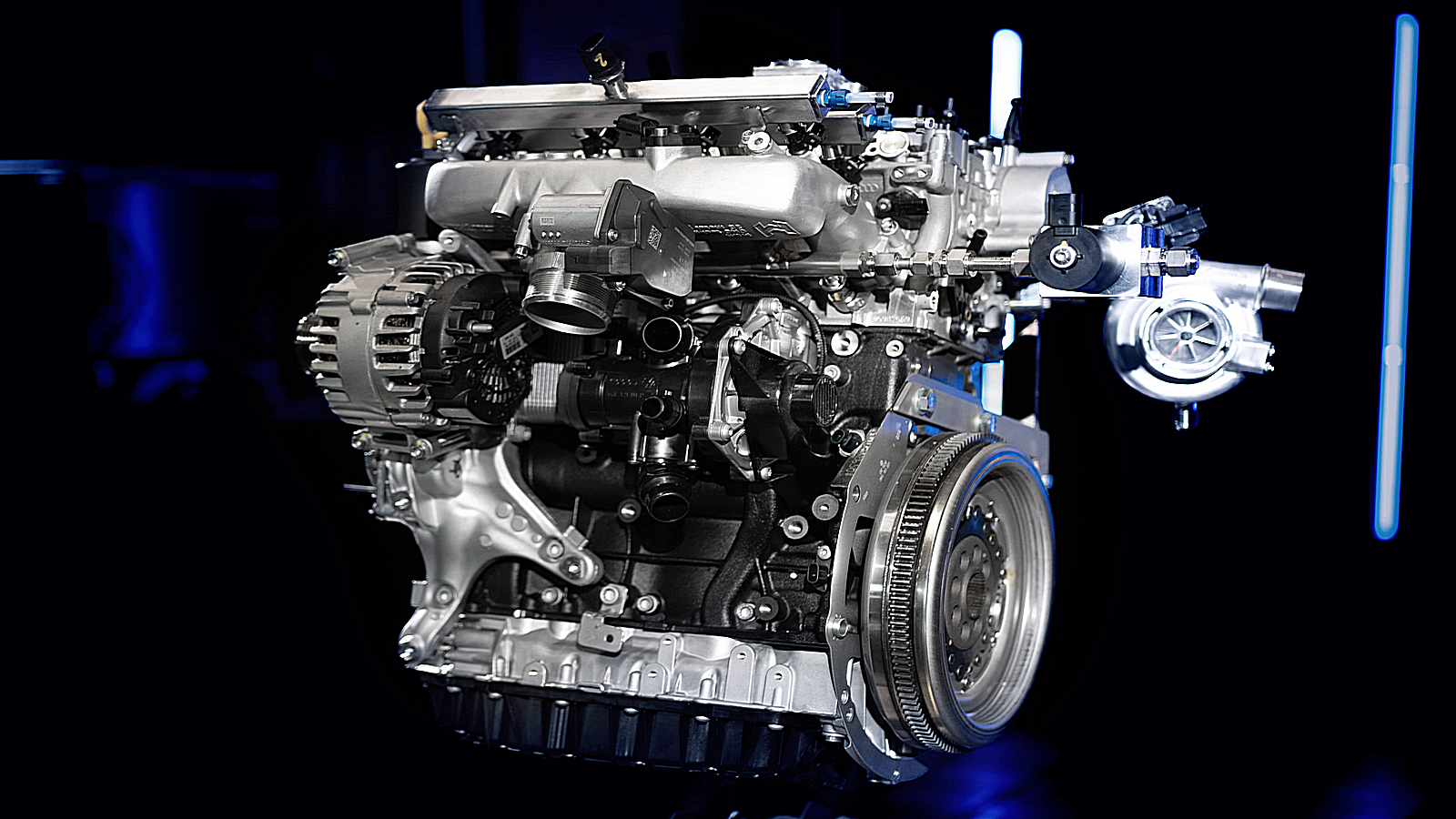

⦁Automotive industry:

Engine components, such as valve covers and intake manifolds.

Gears and bushings.

Clamps and brackets.

⦁Textiles and fibers:

Ropes and nets.

Brushes and bristles.

⦁Electronics and electrical:

Connectors and insulators.

Electronic device housings.

Nylon 6/10. Engineering polymer, with properties intermediate between Nylon 6 and Nylon 12

Other Names and Identifiers:

⦁Polyamide 6,10

CAS Registry Number® 9011-52-3

Properties

1. Flexibility and toughness:

⦁Nylon 6/10 combines the flexibility of nylon 6 with some stiffness of nylon 12.

⦁It is suitable for applications requiring impact resistance and durability.

2. Chemical resistance:

⦁Nylon 6/10 has good resistance to most solvents and dilute mineral acids.

⦁It is also resistant to environmental stress cracking action caused by salts such as zinc chloride.

3. Sustainability:

⦁Nylon 6/10 is a biopolymer based on up to 60% renewable resources.

Applications

⦁Industrial components:

Gears and machinery parts.

Bearings and bushings.

⦁Textiles and fibers:

Ropes and nets.

Brushes and bristles.

⦁3D printing:

Filaments for 3D printers.

Nylon 6/12. Engineering polymer. Nylon 6/10 variant

Other Names and Identifiers:

⦁Polyamide 612.

⦁Nylon 612

CAS Registry Number® 24936-74-1

Specific Properties

1. Increased water resistance

2. Lower melting point

3. Uses and applications.

⦁Both materials find similar applications in various industries, such as manufacturing, automotive, construction and textiles.

⦁Nylon 6/12 is also used in the cosmetics industry.

Nylon 11. Superpolyamide produced from natural resources

Other Names and Identifiers:

⦁Polyamide 11

⦁PA 11

CAS Registry Number® 25035-04-5

European Chemicals Agency (ECHA): 620-040-8

Properties

1. Mechanical strength and flexibility:

⦁Nylon 11 is known for its high strength and flexibility.

⦁It is used in applications requiring durable and impact resistant components.

2. Chemical resistance:

⦁It is resistant to most solvents and dilute mineral acids.

⦁It is applied in fields such as oil and gas, aerospace, automotive, textiles, electronics and sports equipment.

3. Production process:

⦁It is obtained from castor oil by polymerization of 11-aminoundecanoic acid.

Applications

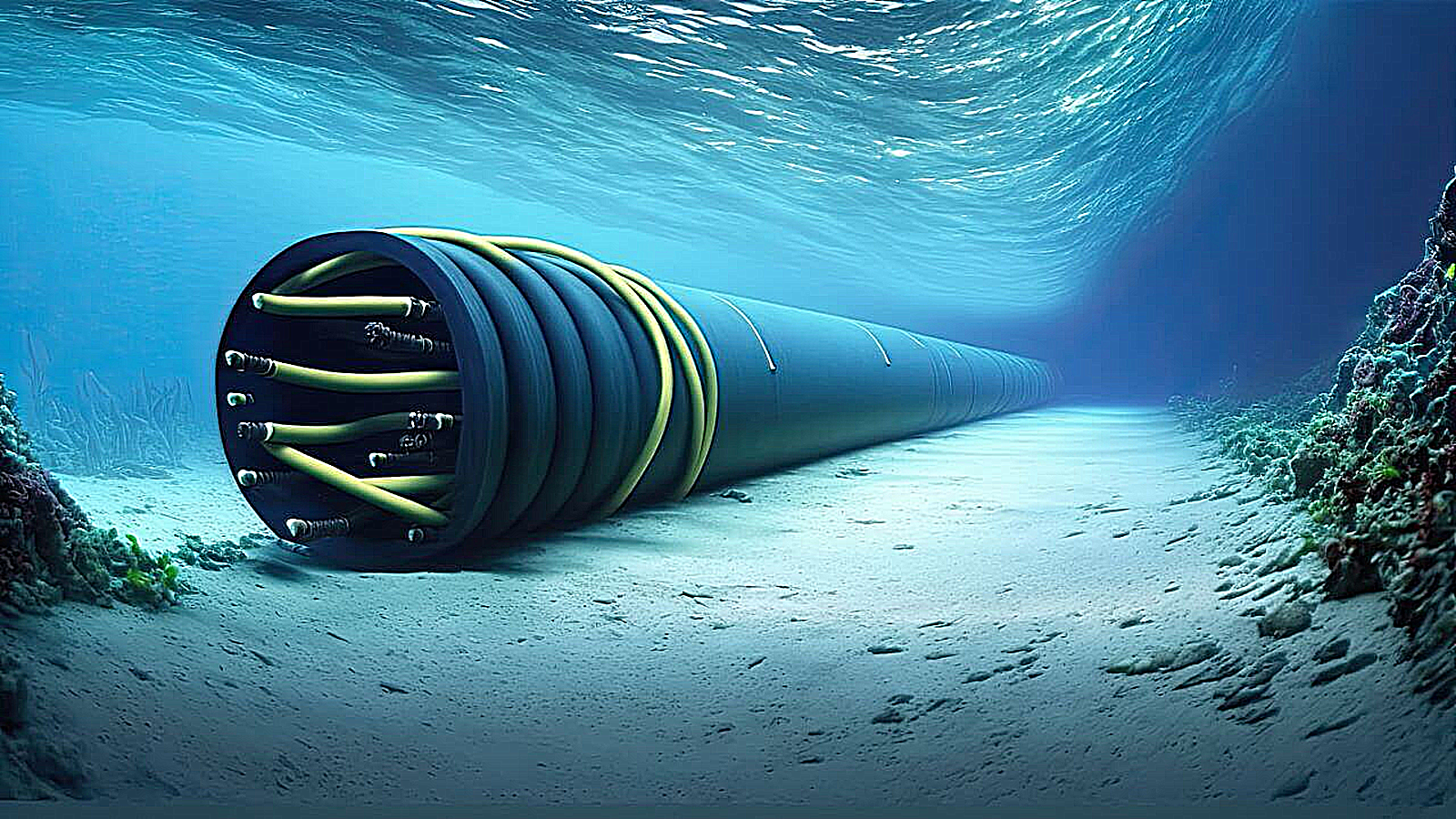

⦁Tubes and hoses:

Due to its low water absorption, dimensional stability and chemical resistance, Nylon 11 is used in fuel lines, hydraulic hoses and medical applications.

⦁Metal coatings:

Applied as a protective coating on metal parts to improve corrosion resistance.

⦁Electronics and textiles:

In electrical cables and insulators.

In textile fibers for sportswear and protective equipment.

Nylon 12. Sturdy, strong and flexible

Other Names and Identifiers:

⦁Polyamide 12

CAS Registry Number® 24937-16-4

European Chemicals Agency (ECHA): 607-456-5

Properties:

⦁Low temperature flexibility.

⦁Low density.

⦁ Its mechanical properties, such as hardness, tensile strength and abrasion resistance, are similar to those of Nylon 6 and Nylon 66.

⦁ It has a wide range of applications as polyamide additives. Nylon 12 is mainly used for films for packaging material in the food industry and sterilized films and pouches for use in the pharmaceutical and medical fields. When added to polyethylene films, it improves water vapor permeability and aroma impermeability.

⦁ It is also prepared in sheet and sintered powder form for coating metals. In the electronics field it is used to coat cables and insulating material, while in the automotive industry it is used to prepare oil and gasoline resistant tubes. In the cosmetics and personal care industries, it is used as a volumizing and opacifying agent in facial and body powders and skin creams. It has also found uses in the textile industry and for the production of sports and leisure articles, among other applications.

Nylon 66/610: the best combination of properties

CAS Registry Number® Nylonn 66: 32131-17-2

CAS Registry Number® Nylonn 610: 9011-52-3

Introduction

The term "Nylon 66/610" does not refer to a specific compound per se. It actually represents a combination of the best properties between Nylon 6,6 and Nylon 610. Let's look at some important details:

Composition and Proportions.

⦁Nylon 66/610 is created by adjusting the proportions of the monomers.

⦁If greater stiffness is sought, the proportion of Hexamethylenediamine (Nylon 66) can be increased.

⦁If greater flexibility is desired, it is possible to increase the proportion of Sebacate Acid (Nylon 610).

Customization according to Properties

⦁Some users may require a nylon with higher mechanical strength, while others may prioritize chemical resistance or flexibility.

⦁Adjusting the monomer ratios allows the material to be tailored to meet these specific demands.

Specific Applications.

⦁Understanding the user's needs is crucial.

⦁Will nylon be used in automotive parts, textiles, medical applications or other context?

We cordially invite you to present your case to offer customized solutions.

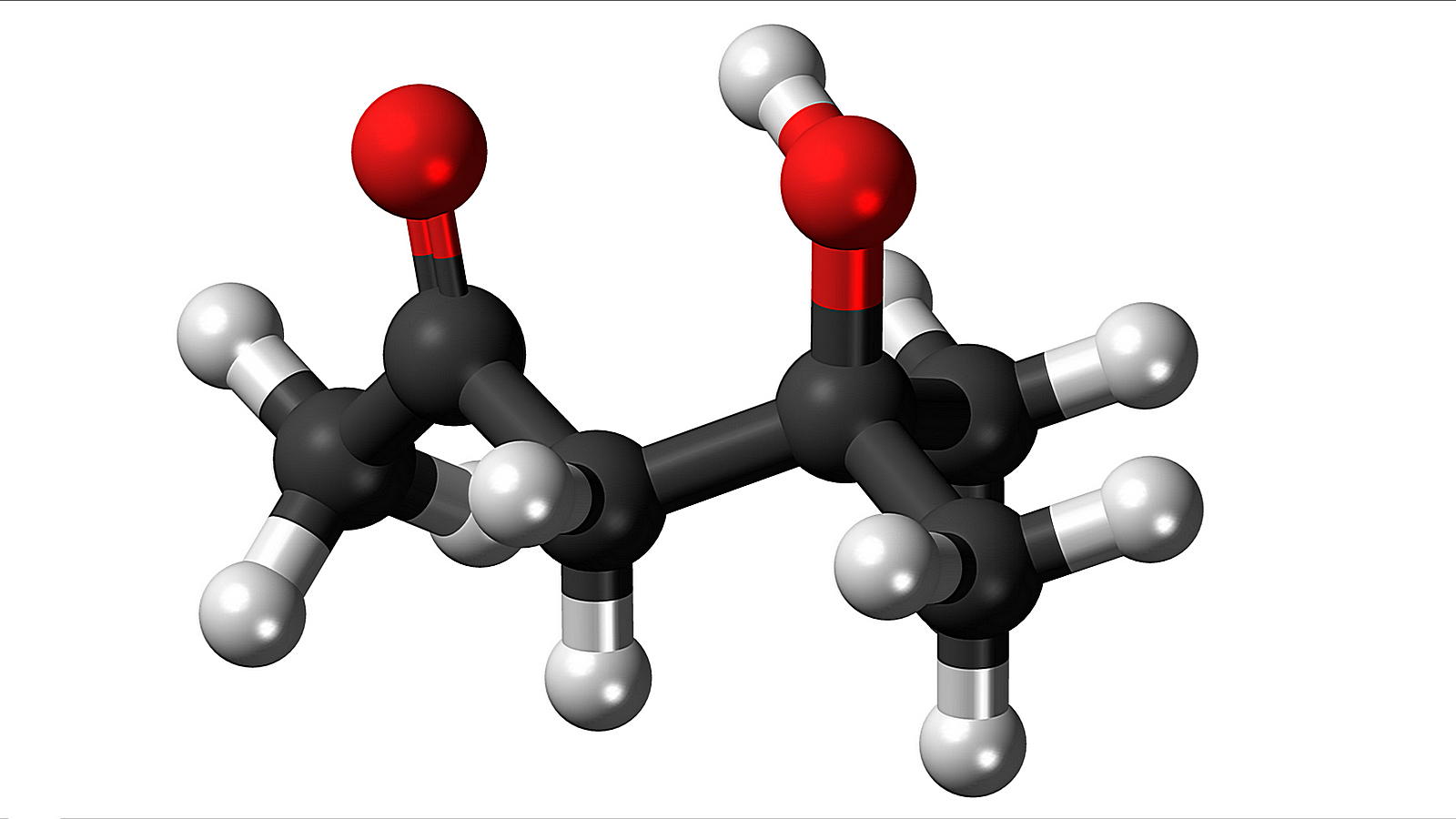

A bright future for plastic

Lactic acid-based polymers have attracted much attention as biomaterials and packaging materials over the past few decades. Lactic acid polymers are biodegradable, low toxic and bioresorbable both in the human body and in nature. Poly Lactic Acid is claimed to be the first commodity plastic produced from renewable resources. The environmental benefits provided by polymers based on lactic acid make their future more promising in certain application areas. Materials based on lactic acid polymers have found their applications mainly in the field of biomedicine and as packaging materials for short-term use. However, the mechanical properties of poly lactic acid and its thermal stability are limited, which restricts its use in applications demanding high performance.

A complete range of Lactic Acid Polymers.

Other Names and Identifiers:

⦁ Polylactic Acid.

⦁ Poly (Lactic Acid)

⦁ PLA

CAS Registry Number® 26023-30-3

CAS Registry Number® 26100-51-6

European Chemicals Agency (ECHA): 825-250-5

Polylactic acid or poly lactic acid (PLA) is a thermoplastic polyester, a polymer or bioplastic consisting of elements similar to lactic acid, with properties similar to those of polyethylene terephthalate (PET) used to make packaging, but which can also be biodegradable under certain conditions at temperatures of around 60 °C. It can be degraded in water and carbon oxide. It can degrade in water and carbon oxide.

It is a thermoplastic whose base materials are obtained from corn or cassava starch or sugar cane.

This plastic material is being widely used in sectors such as food, packaging and others, to obtain, through injection molds, thousands or millions of identical pieces that allow obtaining these parts at very low costs in all aspects.

The main benefit is environmental, as it is biodegradable after use.

Products

• High Purity Biodegradable Material PLA, Granules

• High Quality Compostable Plastic Raw Material. Polylactic Acid Resin Powder, PLA

• Low Melt Index FEP F46 Resin for Valve, Pump and Tube Coating with Tetrafluoroethylene Hexafluoropropylene Copolymer Molding Method

• Photodegradable PLA Plastic Material for Plastics

• Biodegradable Highly Transparent Filament PLA Resin for Packaging Film

• Corn Starch Biodegradable Plastic Granules Polylactic Acid PLA Resin for Small Liquid Sipping Tubes

• Plastic Granules Raw Material PLA / Polybutylene Adipate Terephthalate, Accelerated Biodegradable Plastic

• Bulk Modified PLA Biodegradable Plastic for Plastic Bags

• Medical Grade PLA Biodegradable Plastic

• Biodegradable Plastic Biodegradable Plastic PLA Granular PLA Resin

• Polylactic Acid L130, Granular PLA Resin

• Food Grade Biodegradable Plastic, PLA and Polybutylene Adipate Terephthalate, Injection Moldable Plastic

• Modified Biodegradable PLA Plastic, Heat Resistant, Heat Resistant

• Biodegradable Plastic PLA, for Shopping Bags, Rolls and Garbage Bags

• High Quality PLA Filament Black, 1.75 mm, for 3D Printing

• PLA granules, virgin and biodegradable, for Blow Molding for Shopping Bags

• Masterbatch High Concentration Black, Colorant for PLA

• Ingeo 6202D Resin, Biobased Polylactic Acid, Biodegradable and Compostable

• Bio PLA-Revo De290 Injection Molding Resin

• Biodegradable Plastic, Mixture of PLA with Polybutylene Adipate Terephthalate

• Transparent Plastic in High Quality PLA Granules

• Luminy Lx575 Biodegradable PLA Luminy Lx575 Biodegradable PLA Resin, PLA for 3D Printing

• Filmic Grade Virgin Recycled PLA for Chemical Use

• Biodegradable PLA 4043D, for Blown Film Extrusion

• Biodegradable Polylactic Acid Resin, PLA 4032D

• Biodegradable Virgin PLA, PLA Beads

• PLA 4043D Polylactic Acid, PLA 4043D, for 3D Printing

• PLA Extrusion Sheets, 3D Printing Filament

• PLA 3001D Biodegradable Plastic PLA 3001D, for Blown Film

• PLA PA612 Plastic, High Stiffness and Good Flexibility

• PLA Plastic, Injection Blow Molded, for 3D Printer Filament

• Polybutylene Adipate Terephthalate, Compounded with PLA; for Blown Film for Shopping Bags

• Polylactic Acid PLA Plastic 2003D

• PLA Plastic 4043D, Biodegradable Material for Blown Film Extrusion

• Cellulose Acetate Mixed with PLA for Fibers

• PLA Plastic Non-Toxic, Non-Toxic PLA Plastic for Blown Film, for Waste Bags

• PLA Lx175, Biodegradable Granules for 3D Printing

• Fully Biodegradable PLA Plastic for Injection and Extrusion Molding

• Polylactic Acid Biopolymer Film

| Item | Appearance | Density (g/cm³) | Moisture (%) | Monomer Content (%) | MFR (190°C/2.16kg) | D-content (%) | Melting Point (°C) | Glass Transition Temp (°C) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| FY201 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 30 | <1 | 175 | 60 | 50 | ≤5 |

| FY202 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 30 | 2 | 155 | 60 | 50 | ≤5 |

| FY204 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 18 | 4 | 165 | 60 | 45 | ≤5 |

| FY401 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 18 | <1 | 175 | 60 | 50 | ≤5 |

| FY402 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 18 | 2 | 155 | 60 | 50 | ≤5 |

| FY404 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 18 | 4 | 165 | 60 | 45 | ≤5 |

| FY601 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 9 | <1 | 175 | 60 | 50 | ≤5 |

| FY602 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 9 | 2 | 155 | 60 | 50 | ≤5 |

| FY604 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 9 | 4 | 165 | 60 | 45 | ≤5 |

| FY801 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 4 | <1 | 175 | 60 | 50 | ≤5 |

| FY802 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 4 | 2 | 155 | 60 | 50 | ≤5 |

| FY804 | Transparent Translucent | 1.24 | ≤0.04 | ≤0.3 | 4 | 4 | 165 | 60 | 45 | ≤5 |

Superheavy residues from the Oil Industry

These components, present in crude oil, are extremely dense and viscous. Their high molecular weight and complex chemical structure make them challenging to process and utilize in the petrochemical industry. Special refining techniques are often required to extract value from these residues, which highlights their importance in the industrial context.

Asphalt: Foundation of Modern Infrastructures

European Chemicals Agency (ECHA): 200-578-6

International Chemical Safety Cards (ICSCs): 0044

Asphalt, also known as bitumen or tar, is a material widely used in the construction of roads, pavements and roofs. It is obtained from the distillation of crude oil and is characterized by its wear resistance, flexibility and ability to withstand heavy loads. Its application in civil engineering is essential for creating durable and safe surfaces.

Petroleum Coke: Fuel and Industrial Material

CAS Registry Number® 64741-79-3

European Chemicals Agency (ECHA): 265-080-3

Petroleum coke is a by-product obtained during the refining process of crude oil. It is formed by heating petroleum at high temperatures in the absence of oxygen. This carbonaceous material is widely used in industry as a fuel in power plants and as a raw material in the manufacture of electrodes for the metallurgical industry. Its high density and carbon content make it a valuable resource.

Carbon Black: The Power of Pigment

CAS Registry Number® 1333-86-4

European Chemicals Agency (ECHA): 215-609-9

International Chemical Safety Cards (ICSCs): 0147

9 Types:

1. Super Abrasion Furnace (SAF)

2. Intermediate SAF (ISAF)

3. High Abrasion Furnace (HAF)

4. Easy Processing Channel (EPC)

5. Fast Extruding Furnace (FEF)

6. High Modulus Furnace (HMF)

7. Semi-Reinforcing Furnace (SRF)

8. Fine Thermal (FT)

9. Medium Thermal (MT)

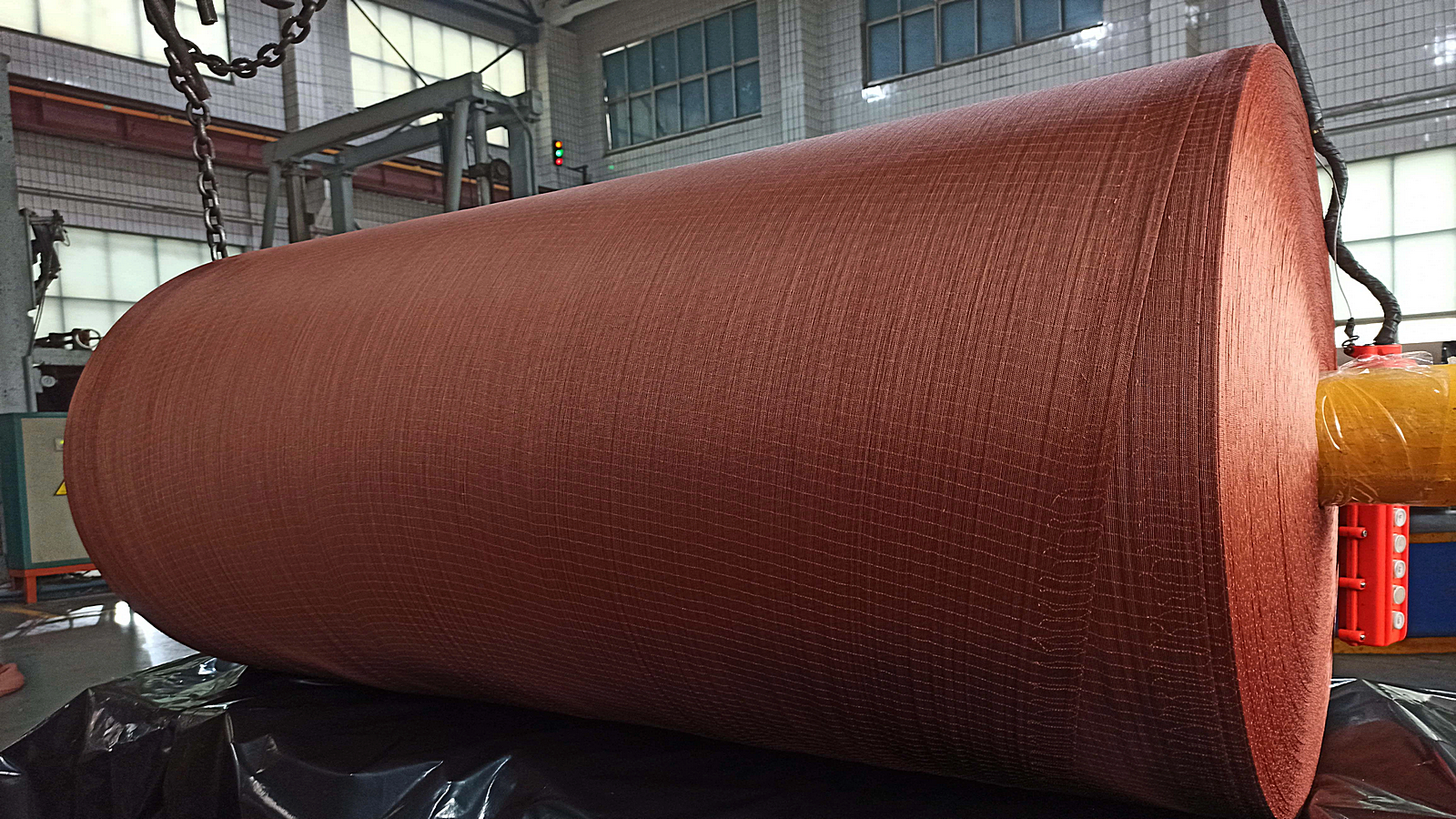

Carbon Black is a product of great importance in various industries. Among them:

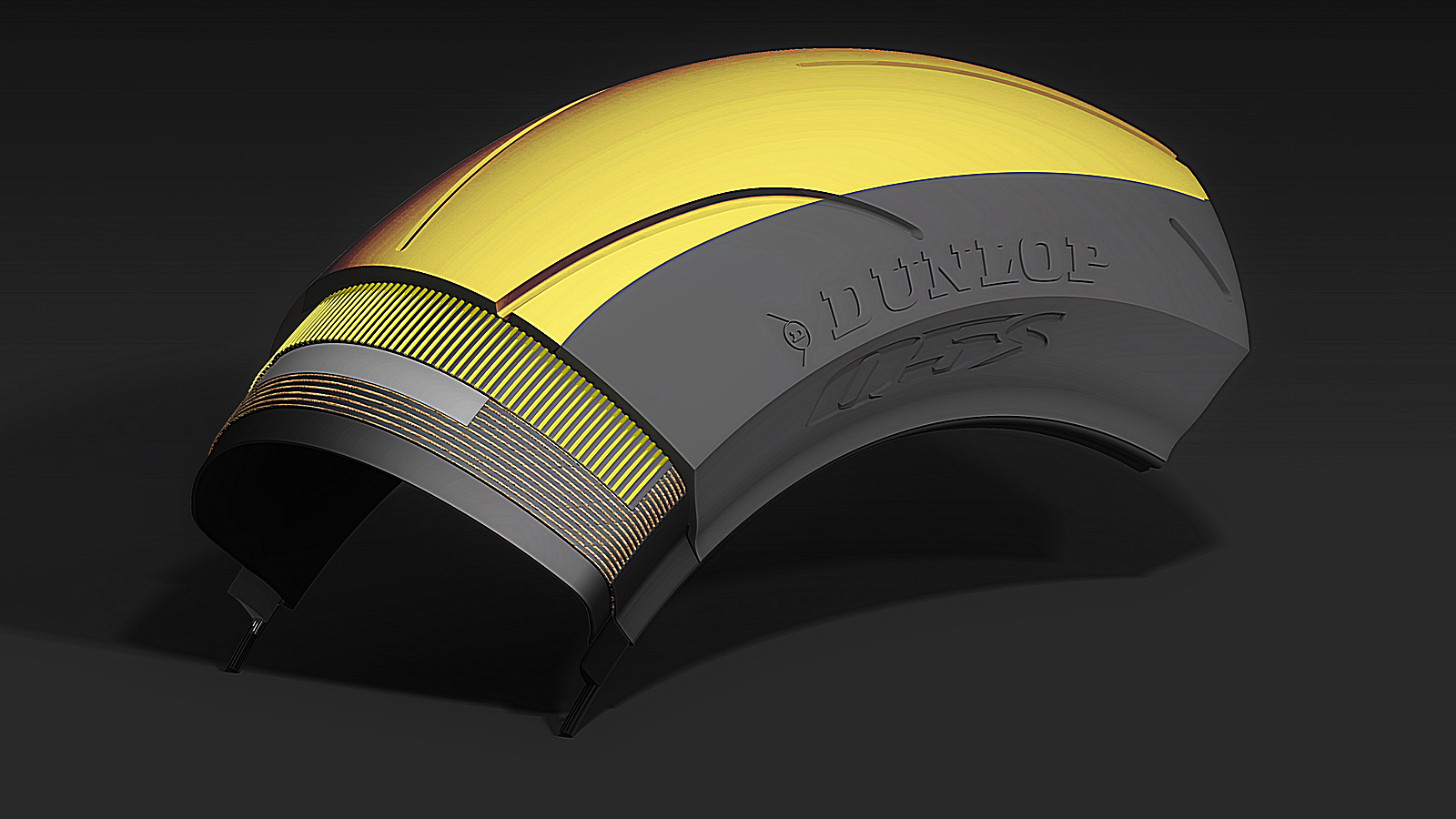

1.-Plastics and rubber industry: Carbon Black is one of the most used elements in these industries due to its effectiveness as a pigment and as a reinforcement in rubber products.

Tires and polypropylene pipes: Carbon black content can constitute up to 30% of the weight of a tire and provides greater durability while maintaining its physical and chemical properties.

3. Electro-conductive and anti-static: Due to its good performance in these areas, it can be used in electronics and in vehicle tank covers.

4. Rubber products: Worldwide, rubber products consume 90% of the carbon black produced.

5. Inks and paints: The remaining 10% of the world's carbon black production is used in inks for newspapers, printers, pens, paints, carbon paper, plastics, food packaging, eyeliners, among others.

6. Reinforcing agent for rubber compounds: Carbon Black is known as the most widely used reinforcing filler for rubber compounds in the world, providing great advantages in the abrasion and stability of these compounds.

7. Production of paints, pneumatic tires, Chinese or pen inks: It is also used for the production of plastics and composites, in addition to having special applications in the production of adhesives, sealants, asphalts, leather, textiles, metallurgy and iron and steel.

Mineral Oils: Lubricants and More

Mineral oils, derived from crude oil, are truly multifaceted in industry. Their versatility ranges from their fundamental function as lubricants in engines and machinery to their role as electrical insulators in transformers. These oils are also used in the manufacture of cosmetic products, as bases for creams and lotions. In addition, their ability to dissolve fat-soluble substances makes them key ingredients in the formulation of medicines and supplements. In short, mineral oils are much more than just lubricants; they are the invisible gear that keeps a wide range of industries moving.

CAS Registry Number® 8042-47-5

European Chemicals Agency (ECHA): 232-455-8

6 Types: (26 Varieties)

⦁Premium Naphthenic Oil (7 Varieties)

⦁Standard Naphthenic Oil (4 Varieties)

⦁Industrial White Mineral Oil (7 Varieties)

⦁Base White Mineral Oil (3 Varieties)

⦁Cosmetic Grade White Mineral Oil (4 Varieties)

⦁Rubber Plasticizing Aromatic Mineral Oil (1 Variety)

White mineral oils are highly refined, petroleum-derived products used in various industrial applications. They play an important role in multiple processes. Here are some of their characteristics and applications:

Characteristics

Color and taste: White mineral oil is colorless and tasteless.

It is non-staining and non-corrosive.

Low tendency to form acids.

Miscible with other petroleum derivatives.

Does not contain carbonizable substances.

Good emulsifying capacity.

Inhibits foam formation.

Applications

Agricultural fumigation (summer oil): Used as an oil to fumigate crops.

Preparation of chemical products: In vehicles and chemical processes.

Component of textile sizing.

Manufacture of glues.

Repellents for industrial use and domestic cleaning products.

Lubrication of natural and synthetic fibers.

Leather industry.

Manufacture of metallic and plastic cables.

There is a Pharmaceutical Grade for white mineral oils. These highly refined oils meet specific standards for use in pharmaceutical and food applications. Examples include:

Pharmaceutical Grade White Mineral Oil (USP).

It is exceptionally pure, colorless and odorless.

Meets FDA, FEUM, USP and NF standards for all food contact products.

Chemically stable and compatible with active ingredients in pharmaceutical formulations.

USP Grade White Mineral Oil

Made with highly refined paraffinic bases.

Free of carcinogenic substances.

Oxidation stable and with low fluorescence.

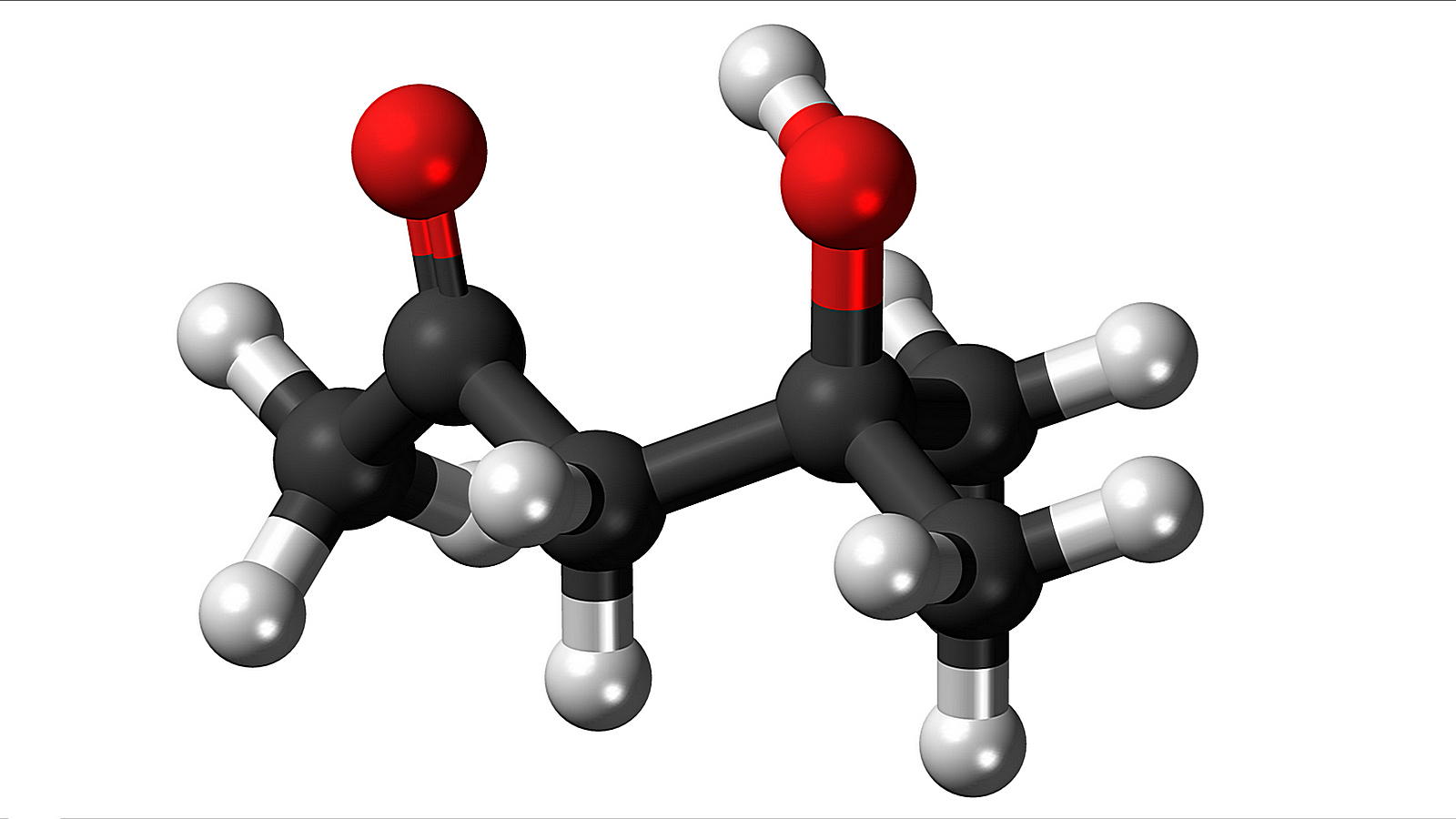

Acyclic and Ethyl Alcohols: Exploring the Chemistry of Hydroxyl Groups

Acyclic alcohols, also known as aliphatic alcohols, are organic compounds containing a hydroxyl group (-OH) attached to a saturated carbon. These alcohols can vary in chain length and functionality. On the other hand, ethyl alcohols, such as ethanol, are simple alcohols with two carbon atoms and are commonly found in alcoholic beverages. Their importance ranges from industrial applications to their role in organic chemistry and human health.

Essential Fundamentals for the Oil and Petrochemical Industry

These elements, although not directly petrochemical, are the foundation on which the petroleum and petrochemical industry is built. Sodium hydroxide (also known as caustic soda) plays a crucial role in biodiesel production, petroleum refining and paper manufacturing. Aluminum oxide (alumina) is essential for the production of aluminum and catalysts. Zinc oxide is used in the manufacture of rubber, paints, ceramics and as an additive in lubricants. These precursors, despite their discreet presence, are the invisible gears that keep the machinery of industry moving.

Diving into Halogens: Exploring Essential Products in the Petrochemical Industry

Its broad industrial spectrum includes applications such as volatile liquid solvents, chemical synthesis, pharmaceutical manufacturing and hygiene, metal cleaning, textile industry and degreasers, as well as other plastic products such as piping and wiring.

They are used in important industrial sectors as non-flammable and non-toxic refrigerants, air conditioning and refrigeration systems. aerosol propellants; refrigerants with low environmental impact; automotive air conditioning systems. refrigerants with a low ecological footprint. foaming agents, as well as refrigerants with low toxicity and low global warming potential.

Chlorobenzene

European Chemicals Agency (ECHA): 203-628-5

International Chemical Safety Cards (ICSCs): 0542

⦁ Descripción: Compuesto aromático con un átomo de cloro unido al anillo de benceno.

⦁ Uso: Disolvente, síntesis química y fabricación de productos farmacéuticos.

❏ Click para agrandar la imagen

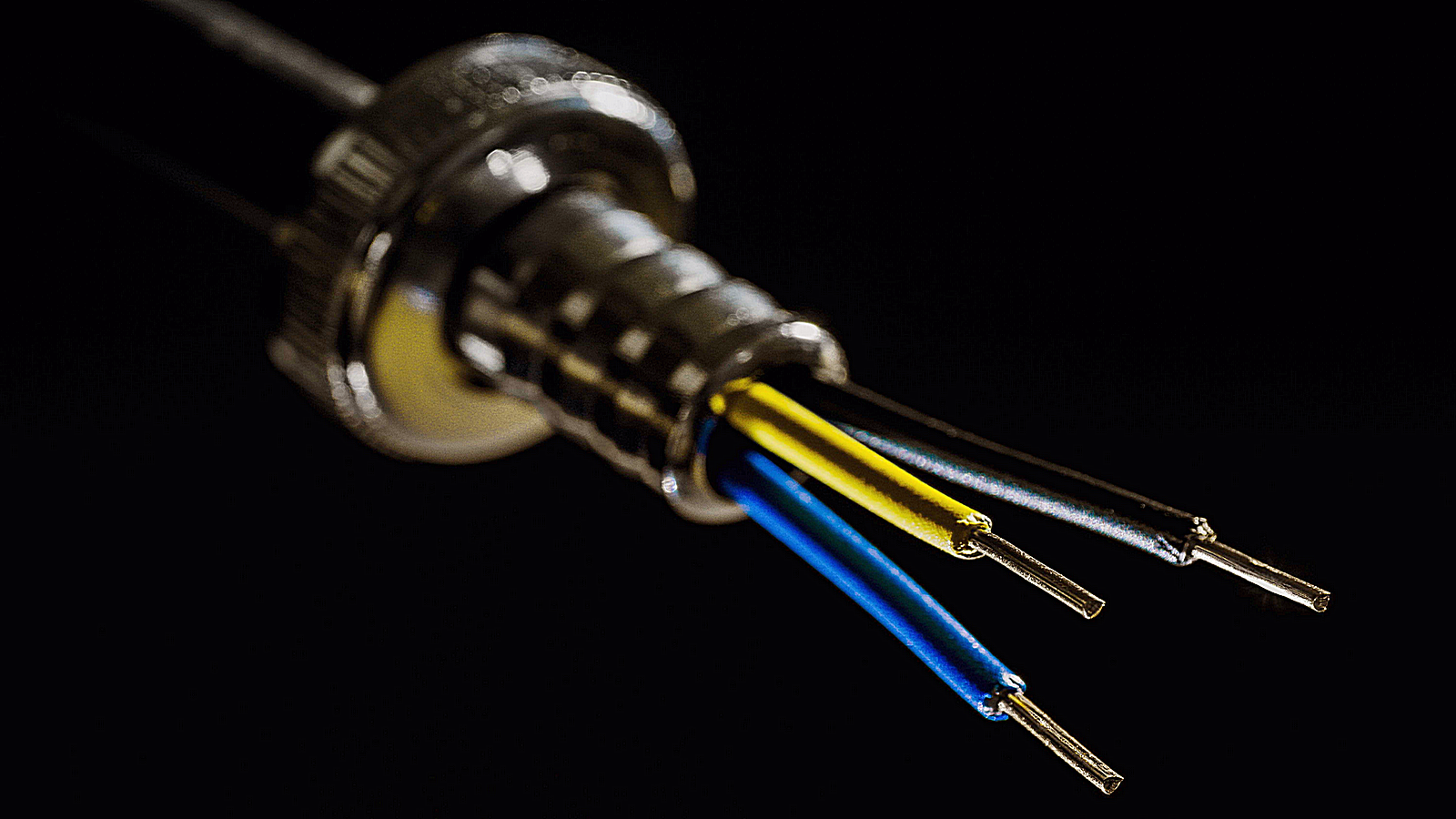

Vinyl Chloride

Otros Nombres e Identificadores:

⦁ Cloroetileno

European Chemicals Agency (ECHA): 200-831-0

International Chemical Safety Cards (ICSCs): 0082

⦁ Descripción: El cloruro de vinilo es un monómero gaseoso que se polimeriza para formar el polímero de cloruro de polivinilo (PVC).

⦁ Uso: El PVC se utiliza en tuberías, cables, revestimientos, ventanas, y otros productos plásticos.

❏ Click para agrandar la imagen

Dichloromethane

Otros Nombres e Identificadores:

⦁ Cloruro de Metileno

European Chemicals Agency (ECHA): 200-838-9

Computer-Aided Management of Emergency Operations: 3154

International Chemical Safety Cards (ICSCs): 0058

HFC-134a (1,1,1,2-Tetrafluoroethane)

Otros Nombres e Identificadores:

⦁ Norflurane

European Chemicals Agency (ECHA): 200-831-0

⦁ Descripción: El HFC-134a es un refrigerante no inflamable y no tóxico.

⦁ Uso: Ampliamente utilizado en sistemas de aire acondicionado y refrigeración.

HFC-152a (1,1-Difluoroethane)

European Chemicals Agency (ECHA): 687-441-8

⦁ Descripción: El HFC-152a es otro refrigerante utilizado en sistemas de refrigeración y aerosoles.

⦁ Uso: Principalmente en aplicaciones de aire acondicionado y como propelente en aerosoles.

HFO-1234yf (2,3,3,3-Tetrafluoropropene)

European Chemicals Agency (ECHA): 616-220-0

⦁ Descripción: El HFO-1234yf es un refrigerante con bajo potencial de calentamiento global.

⦁ Uso: Principalmente en sistemas de aire acondicionado automotriz.

HFO-1234ze (1,3,3,3-Tetrafluoropropene)

CAS Registry Number® 29118-24-9

European Chemicals Agency (ECHA): 810-135-4

⦁ Descripción: El HFO-1234ze es otro refrigerante con bajo impacto ambiental.

⦁ Uso: En sistemas de refrigeración y como agente espumante.

HFO-1336 (Z-1,1,1,4,4,4-Hexafluoro-2-Butene)

European Chemicals Agency (ECHA): 700-651-7

⦁ Descripción: El HFO-1336 es un refrigerante con propiedades de baja toxicidad y bajo potencial de calentamiento global.

⦁ Uso: En sistemas de refrigeración y aire acondicionado.

Tetrachloroethylene

Otros Nombres e Identificadores:

⦁ Percloroetleno

⦁ PERC

European Chemicals Agency (ECHA): 204-825-9

⦁ Descripción: El tetracloroetileno es un líquido incoloro utilizado como disolvente y en la limpieza de metales.

⦁ Uso: En la industria textil, limpieza en seco y como desengrasante.

Trimethylol Propane

Otros Nombres e Identificadores:

⦁ TMP

European Chemicals Agency (ECHA): 201-074-9

Usos y Aplicaciones

⦁ Resinas Alquídicas: El TMP se consume principalmente como precursor de resinas alquídicas utilizadas en recubrimientos y pinturas.

⦁ Monómeros Multifuncionales: Los TMP acrilados y alcoxilados se emplean como monómeros multifuncionales para producir diversos revestimientos.

⦁ Poliuretanos Flexibles: Los derivados etoxilados y propoxilados del TMP se utilizan en la producción de poliuretanos flexibles.

⦁ Revestimientos de Alto Brillo: Los derivados de éter alílico del TMP son precursores de revestimientos de alto brillo y resinas de intercambio iónico.

⦁ Iniciador de Polimerización: El oxetano “TMPO” actúa como un iniciador de polimerización fotoinductible

❏ Click para agrandar la imagen

Descubriendo los Éteres y Peróxidos: Elementos Clave en la Industria Petroquímica

Los éteres y peróxidos son compuestos químicos esenciales en la industria petroquímica. Los éteres se utilizan comúnmente como disolventes y agentes de extracción debido a su baja reactividad y capacidad para disolver una amplia gama de sustancias. Los peróxidos, por otro lado, son conocidos por sus propiedades oxidantes y se emplean en diversas aplicaciones industriales, incluyendo la producción de polímeros y como iniciadores de reacciones químicas. Esta familia de productos es fundamental para la fabricación de materiales avanzados y procesos industriales eficientes.

Diethylene Glycol

Otros Nombres e Identificadores:

○ 2,2'-Oxidietanol

European Chemicals Agency (ECHA): 203-872-2

International Chemical Safety Cards (ICSCs): 0619

❏ Click para agrandar la imagen

Dipropilenglicol

Otros Nombres e Identificadores:

○ Oxybispropanol

○ Oxydipropanol

○ DPG

CAS Registry Number® 25265-71-8

European Chemicals Agency (ECHA): 246-770-3

❏ Click para agrandar la imagen

Methyl ter-Butyl Ether (MTBE)

Otros Nombres e Identificadores:

○ Metil ter-Butil Éter

CAS Registry Number® 1634-04-4

European Chemicals Agency (ECHA): 216-653-1

International Chemical Safety Cards (ICSCs): 1164

❏ Click para agrandar la imagen

Ethylene Glycol Monophenyl Ether

Otros Nombres e Identificadores:

○ Fenoxietanol

European Chemicals Agency (ECHA): 204-589-7

International Chemical Safety Cards (ICSCs): 0538

❏ Click para agrandar la imagen

⮞ Rubbers and their Precursors

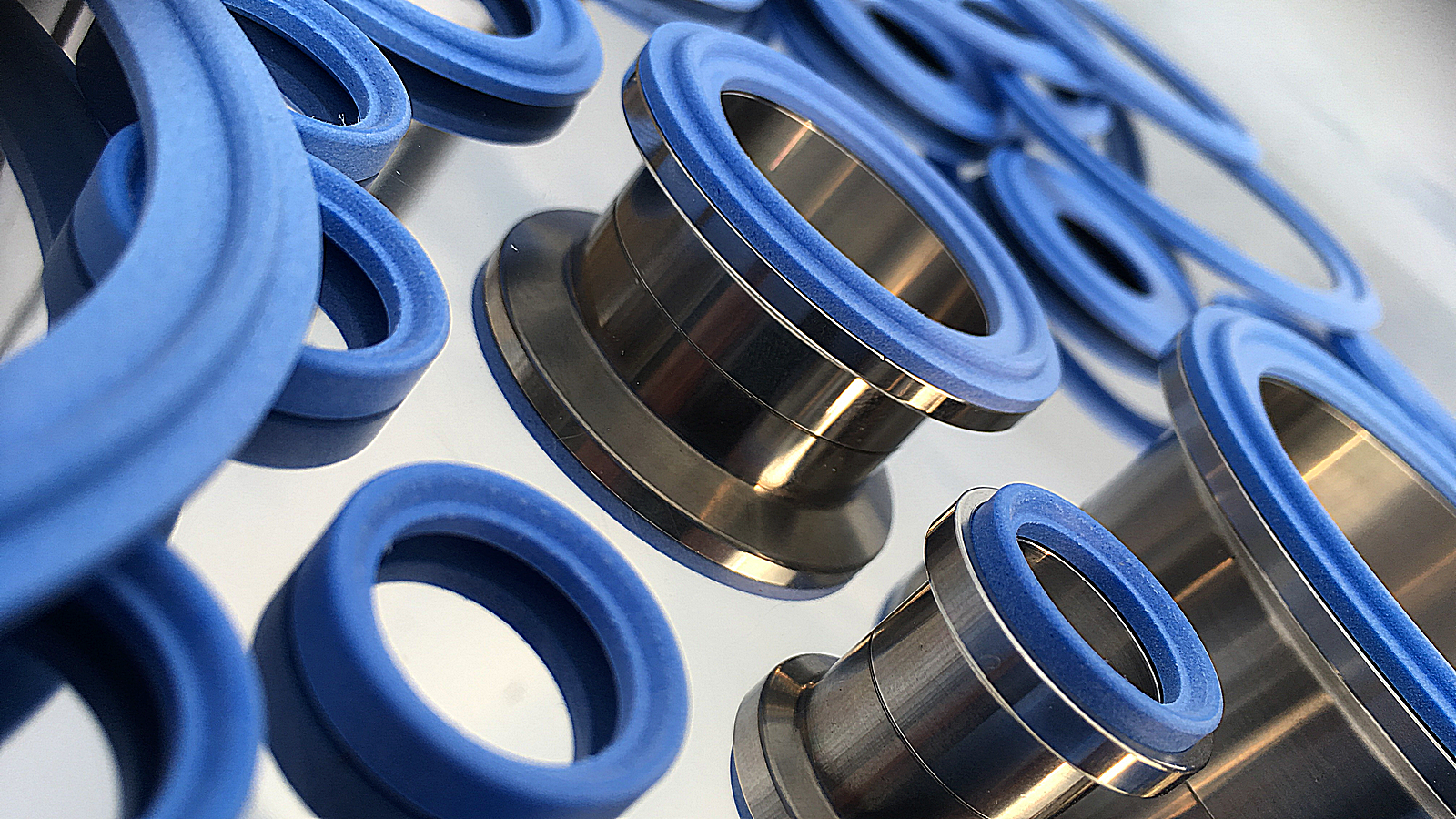

Rubbers and their precursors are vital to the petrochemical industry for several reasons:

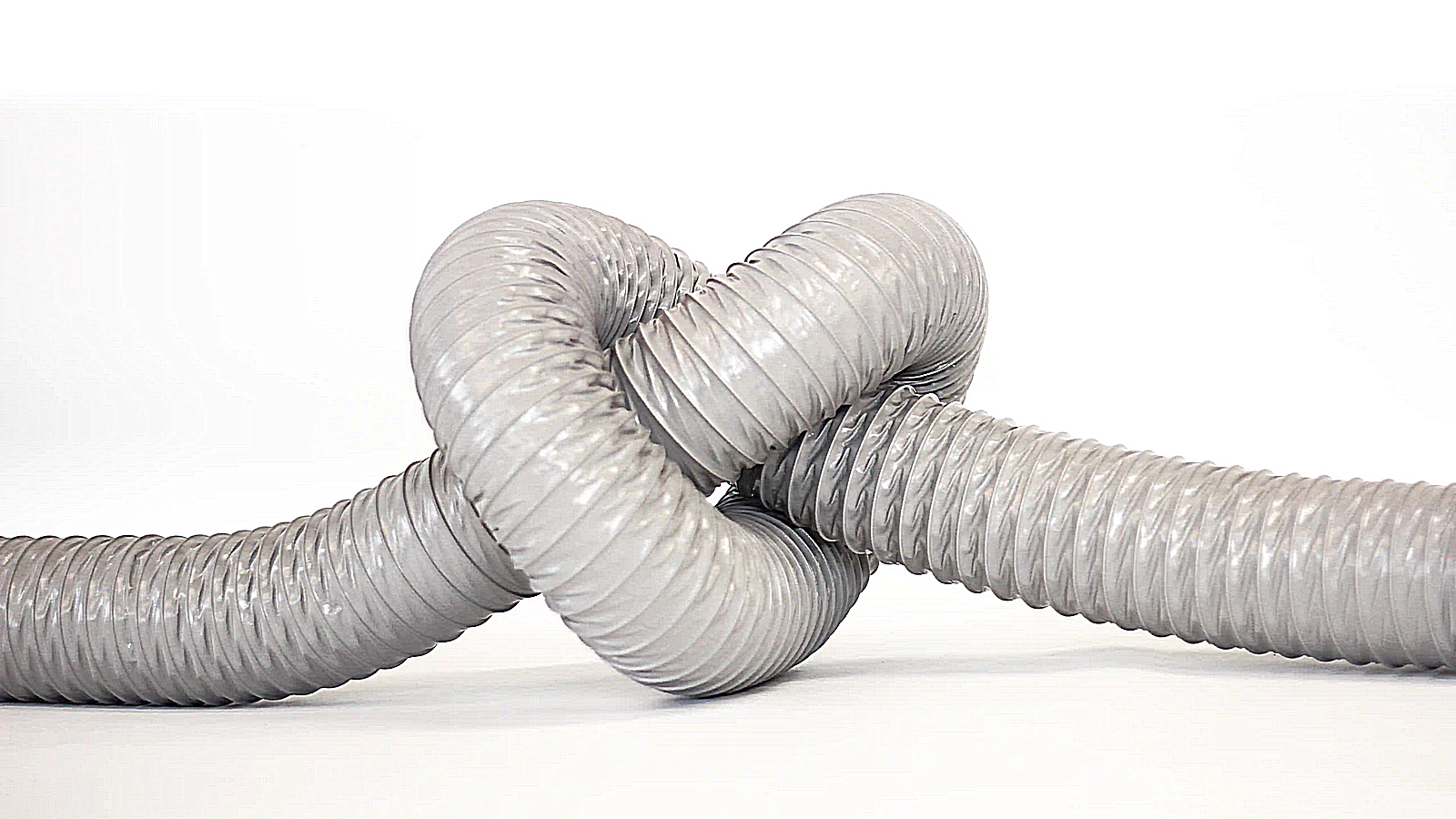

1. Versatility and Unique Properties: Rubbers have an exceptional ability to withstand high temperatures, elasticity, and the ability to absorb vibrations1. These properties make them indispensable in a wide range of industrial applications, from tires to machinery components.

2. Industrial Applications: Rubbers are used in the manufacture of essential products such as tires, seals, gaskets, hoses, and belts. These products are critical to the automotive, construction, manufacturing, and many other industries.

3. Innovation and Development: The petrochemical industry constantly develops new materials and technologies that improve the properties of rubbers, making them stronger and more durable2. This allows for the creation of advanced products that are crucial to industrial progress.

4. Economic Impact: Rubber production and processing generate employment and contribute significantly to the global economy. In addition, rubbers are a key component in the supply chain of many industries.

These reasons underline the importance of rubbers and their precursors in the petrochemical industry, highlighting their essential role in the manufacture of advanced materials and in supporting various industrial applications.

Acrylonitrile-Butadiene Copolymer (NBR)

CAS Registry Number® 9003-18-3

European Chemicals Agency (ECHA): 618-357-1

Ethylene-Propylene Rubber (EPR)

CAS Registry Number® 9010-79-1

European Chemicals Agency (ECHA): 618-455-4

Ethylene-Propylene-Diene Rubber (EPDM)

European Chemicals Agency (ECHA): 616-220-0

⦁ Descripción: El HFO-1234yf es un refrigerante con bajo potencial de calentamiento global.

⦁ Uso: Principalmente en sistemas de aire acondicionado automotriz.

Brominated Poly(Isobutene-Isopropene) Rubber (BIIR)

CAS Registry Number® 68441-14-5

European Chemicals Agency (ECHA): 614-497-2

Poly(Butadiene-Styrene) Rubber [SBR]

Other Names and Identifiers:

⦁ Butadiene-Styrene Copolymer

⦁ SBR (Styrene-Butadiene Rubber)

⦁ Poly(Butadiene-Styrene)

CAS Registry Number® 9003-55-8

European Chemicals Agency (ECHA): 618-370-2

Poly(Isobutene-Isoprene) Rubber [IIR]

Other Names and Identifiers:

⦁ IIR (Isobutylene Isoprene Rubber)

CAS Registry Number® 9010-85-9

European Chemicals Agency (ECHA): 618-457-5

Chlorinated Poly(Isobutene-Isoprene) Rubber [CIIR]

CAS Registry Number® 68081-82-3

European Chemicals Agency (ECHA): 614-265-0

Polybutadiene Rubber (PB)

Other Names and Identifiers:

⦁ Polybutadiene

⦁ Butadiene Polymer

⦁ PB

⦁ BR

CAS Registry Number® 9003-17-2

European Chemicals Agency (ECHA): 618-356-6

Carboxylated Acrylonitrile-Butadiene Copolymer (XNBR)

CAS Registry Number® 9010-81-5

European Chemicals Agency (ECHA): 639-551-2

Essentials for the Petroleum and Petrochemical Industry

La cera de parafina clorada (Chlorinated Paraffin Wax, CPW) es una mezcla compleja de parafina y alcanos n-policlorados. Se produce haciendo pasar gas de cloro a través de cera fundida hasta que reacciona con la cantidad de cloro deseada. El contenido de cloro de la CPW puede variar entre 10% y 70% o más.

La CPW puede ser un líquido viscoso de color pálido a amarillo o un sólido resinoso blando o quebradizo, dependiendo del contenido de cloro. Es prácticamente insoluble en agua, alcoholes inferiores, glicerol y glicoles, pero soluble en solventes clorados, hidrocarburos aromáticos, cetonas, ésteres, éteres, aceites minerales y algunos aceites de corte.

La CPW tiene muchos usos, como:

⦁ Retardante de llama

⦁ Plastificante

⦁ Producción de materiales para cables, pisos, paneles, zapatos, caucho y otros productos

⦁ Recubrimientos y aditivos para aceites lubricantes

⦁ Cardado de lana

⦁ Líquidos de limpieza

⦁ Recubrimiento ignífugo en textiles

⦁ Fabricación de papel de carbono

⦁ Plastificantes secundarios en PVC y otros plásticos

⦁ Pinturas resistentes a la abrasión, como plastificante o como componente del aglutinante

⦁ Plásticos y C18-30 para plásticos rígidos como poliésteres y poliestireno

Parafina Clorada 52

CAS Registry Number® 63449-39-8

European Chemicals Agency (ECHA): 264-150-0

Otros Nombres e Identificadores:

⦁ Chloroalkanes, C14-17

⦁ CAS Registry Number® 85535-85-9

★ Aspectos destacados

☆ Parafina Clorada 52

☆ Cloro: % w/w 52

Parafina Clorada 45

CAS Registry Number® 63449-39-8

European Chemicals Agency (ECHA): 264-150-0

Otros Nombres e Identificadores:

⦁ Chloroalkanes, C14-17

⦁ CAS Registry Number® 85535-85-9

★ Aspectos destacados

☆ Parafina Clorada 45

☆ Cloro: % w/w 45

CAS Registry Number® 63449-39-8

European Chemicals Agency (ECHA): 264-150-0

Otros Nombres e Identificadores:

⦁ Chloroalkanes, C14-17

⦁ CAS Registry Number® 85535-85-9

★ Aspectos destacados

☆ Parafina Clorada personalizada

☆ Grado de Cloración: % w/w, entre 30 y 70

Hexane Isomers

Hexane is usually used as a foaming agent or oil extraction solvent. However, using hexane in its isomeric forms enhances the results to their maximum possible performance, in terms of production efficiency and quality of the final product.

Hexane isomers: as a blowing agent in the manufacture of expanded polystyrene

⦁ Improved blend

⦁ Maximum yield

⦁ Optimal foaming

Hexane isomers: as solvent for the extraction of edible oils

⦁ Improved blend

⦁ Maximum yield

⦁ Improved color and flavor

| Solvent | CAS | Isomer | Alternative Name | Technological Function |

|---|---|---|---|---|

| Hexane | 110-54-3 | Hexane | n-Hexane | Blowing agent in the manufacture of expanded polystyrene | Solvent for the extraction of edible oils |

| Hexane [Isomer 1] | 75-82-3 | 2,2-Dimethylbutane | Neohexane | Blowing agent in the manufacture of expanded polystyrene | Solvent for the extraction of edible oils |

| Hexane [Isomer 2] | 79-29-8 | 2,3-Dimethylbutane | Diisopropyl | Blowing agent in the manufacture of expanded polystyrene | Solvent for the extraction of edible oils |

| Hexane [Isomer 3] | 96-14-0 | 3-Metilpentano | Diethylmethylmethane | Blowing agent in the manufacture of expanded polystyrene | Solvent for the extraction of edible oils |

| Hexane [Isomer 4] | 107-83-5 | 2-Methylpentane | Isohexane | Blowing agent in the manufacture of expanded polystyrene | Solvent for the extraction of edible oils |